Straps to Go produces sail ties from both polypropylene and polyester webbing. The standard webbing width is 1″ although we can make them whatever width you want.

Construction

I am a bit “old school” and like to keep my sail ties simple. Just a length of webbing with a loop sewn in one end works for me. A bit better is to have the webbing in the loop twisted so that the eye stays open when you are trying to thread the other end through.

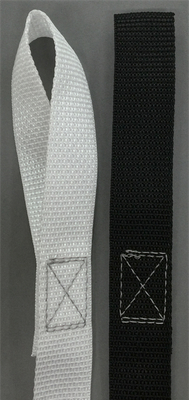

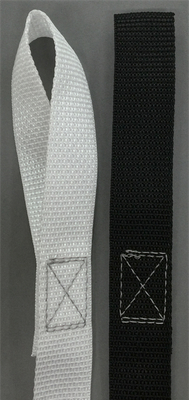

On the left you have a sail tie with a twisted loop, on the right (the black strap) the loop is not twisted.

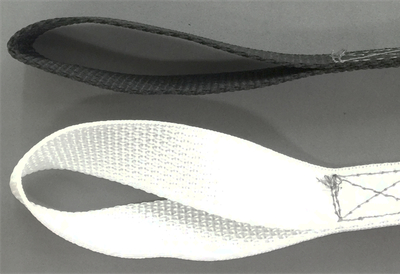

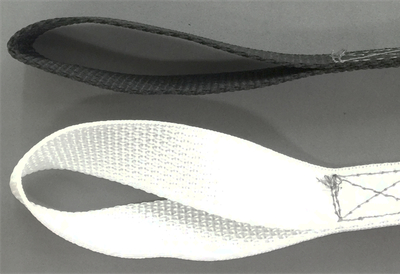

The side view shows how the twisted loop in the white sail tie stays open even if the loop has been pressed closed.

Others like to have a buckle on their sail tie, once adjusted all you have to do is snap is shut. We have had customers buy these ties in different colors so that they know that the blue ones are the longest, red are a a medium length and black are the shortest (or whatever colors suit your fancy).

The sewing on all of our sail ties is done using polyester thread with advanced UV protection. It is made in the USA by A&E and is a TEX 90 size. We use a Box-X stitching pattern.

Materials

Polypropylene webbing is the standard we use. It is inexpensive and doesn’t adsorb water which is also nice and comes in a bunch of colors. What polypropylene doesn’t like is sunlight. It will degrade if you don’t cover your sail ties with a sail cover.

Polyester webbing will stand up to ultra-violet exposure. It will adsorb a bit of water, more than polypropylene but much less than nylon. We only carry this webbing in black and white. Our white polyester webbing has a much better feel to the hand than the black so it would be my choice if I were replacing my sail ties.

Over the years I have sailed on boats with a bunch of different solutions for sail ties. The most basic, just a length of webbing with no eye works fine but is a bit more difficult to get secured than webbing with an eye in one end. Elastic cords were the rage for a while as was my black eye when I got hit from one of the plastic balls on the end of the cord. Then there were the contraptions that went from your mast to the end of the boom with a number of elastic ties hanging from them. Once you had these untangled and installed, the rest of the crew was cleaned up and in the bar.

Ordering

If you are looking for sail ties with a sewn loop, check out https://strapstogo.com/straps/sail-ties.php

If you want ones with side release buckles, https://strapstogo.com/straps/side-release-buckle-straps.php

In either case they will be promptly produced and shipped to you. We ship using Priority Mail which is speedy and only costs $7.00 no matter how many you order.

Questions? Give Rollie a call at (253) 627-6000.