You want a logo on your webbing and would like it to be in color. Quickly you will enter the world of dye sublimation “printing”, often called dye-sub “printing”. This is a process that turns ink into a gas that will bond with polyester. The end result is something that has amazing vibrancy and longevity.

If you ride bicycles, jerseys are “printed” that way and will last longer than most of us care to wear them. Spandex exercise wear is dye-sub “printed”. Now the industry even coats metal and coffee cups with polyester so they can be “printed”. It is an amazing technology.

Dye-sub “printing” does have its downsides when it comes to webbing. It only works on polyester, not nylon or polypropylene. Webbing is thicker than clothing and dye-sub “printing” only will dye the surface.

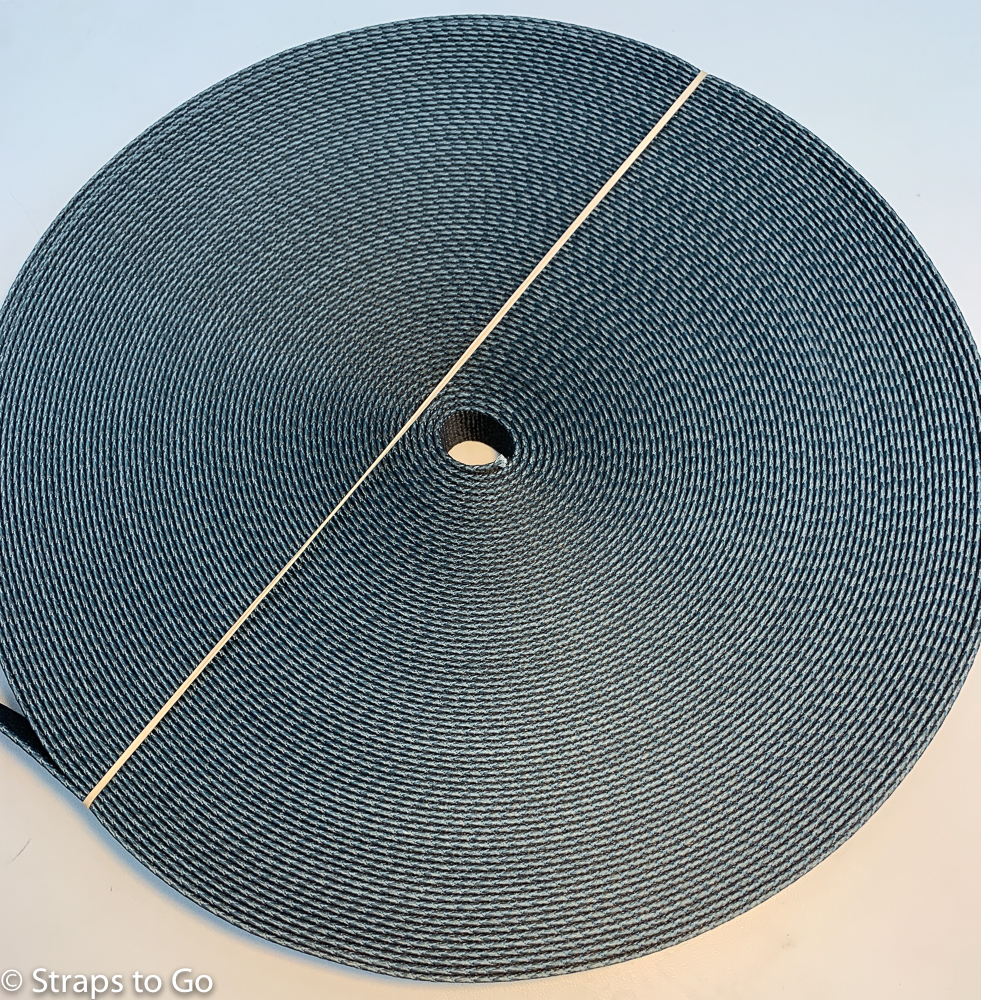

Above is white polyester webbing that has been “printed” black. From this view it looks great but-

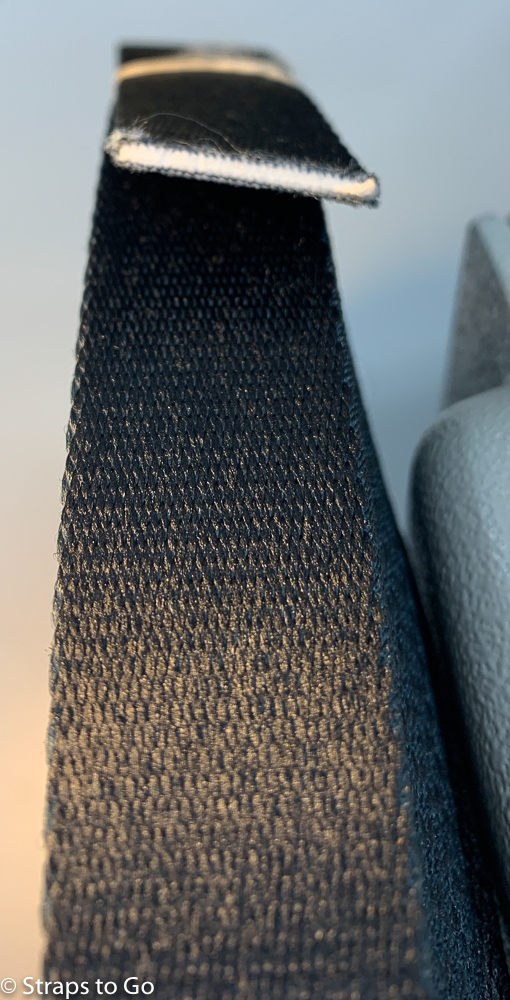

here is the end of the roll. You can see that the center of the webbing is white and should your strap experiance abrasion, you will soon see that white.

This is the side of the same roll of webbing. Once again the white is showing through.

We are dealing with a dyeing process that requires that the ink be darker than the material being dyed. With webbing one starts with white and then you dye the darker colors. If there is white in the image, you just don’t dye in that area. To get a black strap with white lettering you start with white webbing and dye everything other than the lettering.

Advantages of dye sublimation:

- Short production runs are possible

- True 4 color process

- Fast turn around (compared to production runs of webbing with a logo)

- You can have different images/colors on each side of the webbing

Disadvantages of dye sublimation:

- Polyester only

- Not abrasion resistant

- Cut ends and the sides of webbing will be white

Is this the right technology for your application? Give us a call and we will help you figure it out. (253) 627-6000