Your lifejacket (PFD) has a broken buckle, wouldn’t it be nice just to replace the broken half rather than buy a whole new lifejacket? If only it was simple to find the correct buckle.

When a manufacturer wants to sell a lifejacket to the public (in the United States) they need to get it approved by the United States Coast Guard. That entails working with a testing laboratory like Underwriters Labs who will review the design and then test product samples to ensure that they meet the proper USCG specification. After passing the results are sent to the USCG who will then issue the approval. Once in production the testing lab will continue to evaluate the production, making sure that every life vest meets the requirements.

Part of this whole process is specifying the materials used. Foam, fabric, webbing, buckles and even the labels are specified and can not be changed without going through the approval process once again.

Since we are interested in the buckles, take a look at the image above. That Kent commercial lifejacket uses two different buckles on its closure straps. If both male halves (the most common part to break) were to break you would need to source two different buckles which might not have come from the same buckle manufacturer. Most of us who sell replacement buckles work with one primary manufacturer. Ours is American Cord and Webbing (ACW) and their parts are not interchangeable with buckles made by Fasnap, ITW Nexus or others. Even to get this far you need to identify the buckle manufacturer and since most “value priced” lifejackets are made overseas, so are the buckles and those buckle manufacturers do not have distribution in the United States.

If you happen to have a heavy duty sewing machine you might think about replacing both halves of the buckle with something you can easily find. Unless you use the exact buckle and sew it in the same manner and use the same thread you will void the USCG approval. The lifejacket would no longer be counted as part of your carriage requirements. Worse yet, should something go really wrong and the lifejacket needed to be used- and then failed, the vessel owner would be liable.

Enough doom and gloom….

We do carry two products made by ACW that are used on USCG approved life jackets.

-

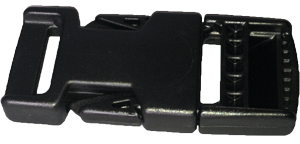

- Type V Side Release Buckle

Designed for use with 1″ webbing but no longer in production. We purchased the last of ACW’s inventory and as of March 2018 have a good supply.

Designed for use with 1″ webbing but no longer in production. We purchased the last of ACW’s inventory and as of March 2018 have a good supply.

Order 1″ Type V Side Release Buckles - Type V Slide

Designed for use with 1″ webbing.

Order 1″ Type V Slides

- Type V Side Release Buckle

ACW only makes these parts for 1″ webbing. If you need either, or both, of these place an order online or give us a call at (253) 627-6000 and we will get them right out to you.