Watching The Ocean Race getting ready for the Southern Ocean brings back memories of tough times I have had while sailing. One of those was taking the yawl Temptation from Anacortes, WA to Vancouver BC after she had been repowered.

We were going to Vancouver for the Southern Straits race which is normally on Easter weekend. The race starts on Saturday, so Thursday we were in Anacortes heading north through the Straits of Georgia on a particularly foul day.

Temptation had a brand new engine that hadn’t been put to the test. We were all concerned about reliability, but the race was calling. Leaving port we were able to sail but the owner finally decided we could make better time under power.

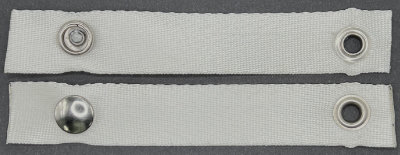

Time to lower the sails. Two of us were sent to the foredeck to handle the jib. We got the sail down, but controlling it on deck was a problem. Laying on top of the sail with seas washing over, the two of us were able to get gaskets (lengths of polyester webbing) around the sail and lifeline stanchions. We were wet, it was dark and we still had a ways to go.

When we finally were tied to the dock in Vancouver the senior (by age) member of the crew announced that he was making everyone a hot buttered rum. At least, that’s what I heard. Get the alcohol stove going, heat water and prepare our beverages. For some reason we didn’t have much light in the cabin, so we couldn’t see what was going on.

Our hot buttered rums were delivered but after a single sip we could all tell something was amiss. There was no sweetness in our drinks, just hot water and rum in a 50/50 mix. I believe we all finished our drinks but they could have been so much better!

Temptation Style Gaskets

Ocean Race Special Pricing

To help celebrate The Ocean Race, we are offering T-Style Gaskets (Temptation Style), made from heavyweight white polyester webbing. Each gasket is 8′ in length and they are sold in packages of 5. For the duration of The Ocean Race 2023 we will be selling a pack of 5 for $19.95 plus shipping.