One of the more useful straps we sell is the Cam Buckle Strap. They offer everything one might want out of a strap:

⇒ strong

⇒ easy to use

⇒ affordable

I carry a number of these in my truck to secure loads and some times they even are used to secure garbage cans.

For 2021 we have changed the cam buckle used in our straps. It is now a zinc coated steel buckle which is much stronger than what we previously used.

It has a breaking strength of 1100 pounds and buying them in volume has allowed us to upgrade the webbing we use to a much stronger grade at the same pricing.

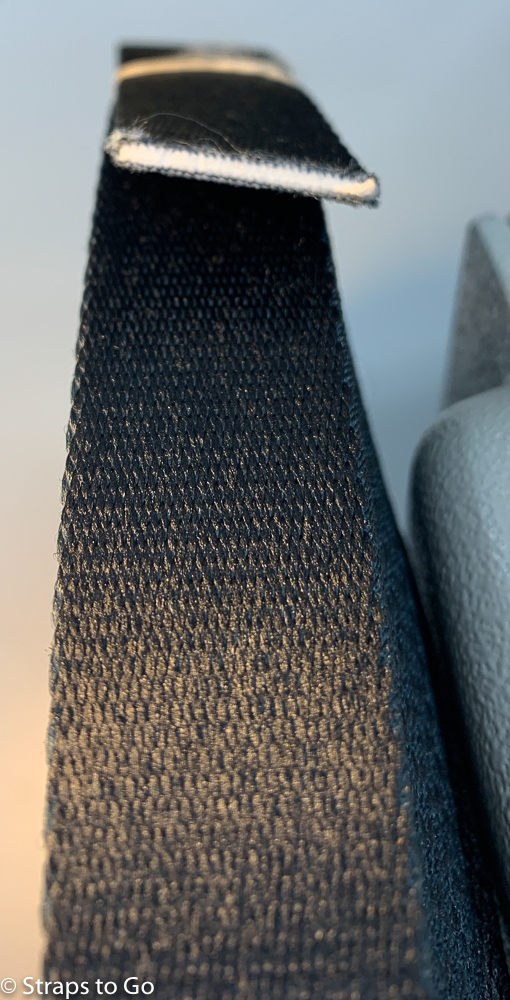

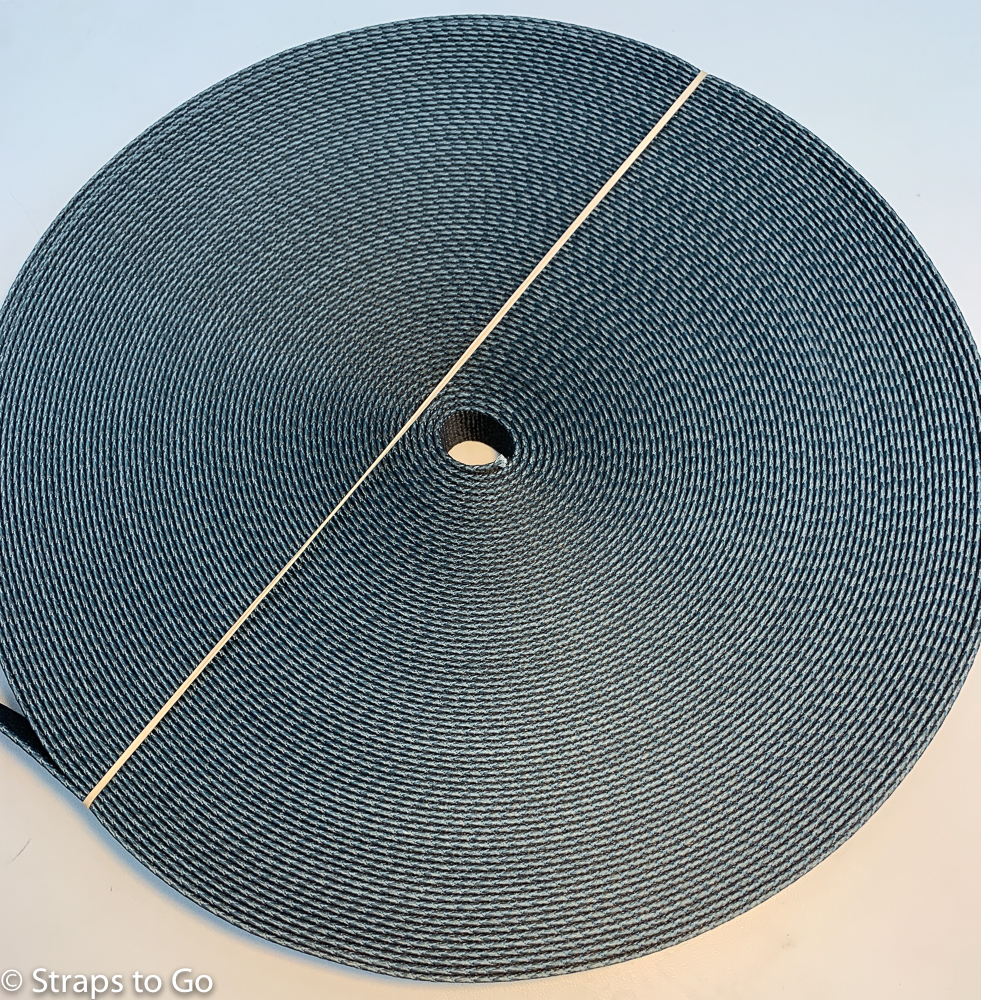

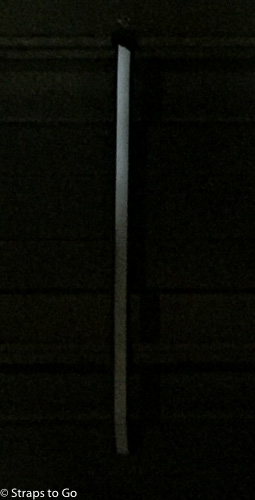

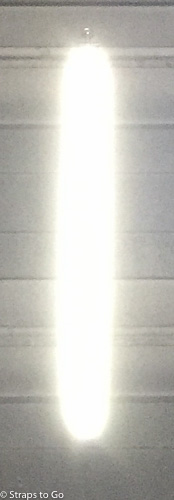

Our nylon straps are available in black, royal blue (shown above), red and yellow. The webbing has a breaking strength of 2750 pounds although the weak point on the strap is the buckle. The raw end is cut at an angle to make insertion into the buckle simple and it is heat sealed.

The polypropylene version only comes in black and the webbing has a breaking strength of 800 pounds. There isn’t much of a price difference between the nylon and polypropylene version, it boils down to which webbing is best for your application.

Cam Buckle StrapsBoth of these models are much superior to what we have been able to offer in the past with no increase in price. Give them a try, I think you will like them.